Post by mrblackcat on Jan 2, 2019 3:31:49 GMT

The Desert Eagle gas cylinder... from sarcasm to solutions, this is a first hand look at the dimensional variation and potential effects of these variations on the function of the Desert Eagle pistol.

The intent of this writing is to possibly aid in troubleshooting a problem pistol. If nothing else, should you have trouble with a Desert Eagle, you could use this information to rule out a high-tolerance gas cylinder as part of the issue.

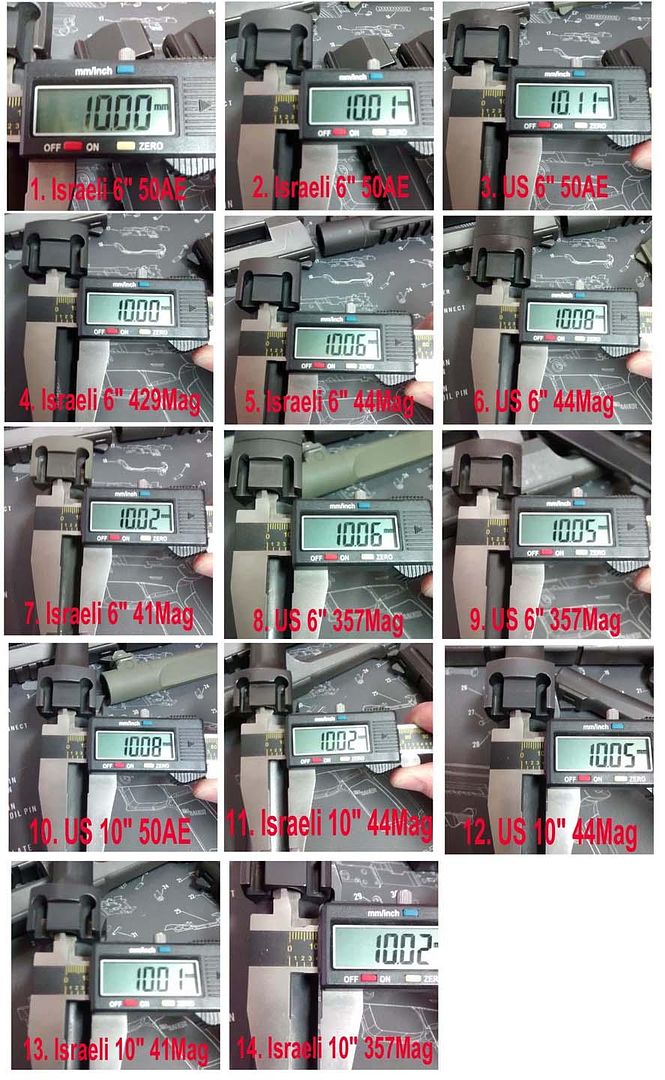

First off… a picture is worth at least 1000 words… so have a look at 14 barrels I currently own…

# Barrel Length Diameter

1 Israeli 6 50AE 10.00mm

2 Israeli 6 50AE 10.01mm

3 US 6 50AE 10.11mm

4 Israeli 6 429DE 10.00mm

5 Israeli 6 44Mag 10.06mm

6 US 6 44Mag 10.08mm

7 Israeli 6 41Mag 10.02mm

8 US 6 357Mag 10.06mm

9 US 6 357Mag 10.05mm

10 US 10 50AE 10.08mm

11 Israeli 10 44Mag 10.05mm

12 US 10 44Mag 10.02mm

13 Israeli 10 41Mag 10.01mm

14 Israeli 10 357Mag 10.02mm

Although I live in the US, I used metric measures because of the higher resolution.

Even with the relatively low precision of calipers, have a look at the numbers relative to each other and you will see where this is going pretty quickly.

Jumping straight in...

Barrel number 1 is my very first 1993 Mk VII 50AE barrel. It has over 4000 rounds through it at this point. With this barrel and its gas cylinder dimensions, you will never understand the term “limp-wristing” because it doesn’t happen… this is mostly due to optimal (proper?) gas cylinder clearance, between the piston and cylinder.

Barrel number 3… the third barrel I bought. I wanted a muzzle brake on a 50AE barrel, and didn’t want to modify my original barrel, so I bought this barrel for that purpose… but it doesn’t work well enough to bother using. I have posted about this in other threads, but long story short, it has been back to Magnum Research twice and I am told it functions fine and is within spec. The point being that if you have this issue, you are probably on your own. They must test these things in a vice, with dynamite for ammo is all I can figure.

With barrel 3, some functionality can be achieved with the hottest of rounds, locked elbows, and the muzzle brake helped, probably by keeping the gun more flat.

However... before I retired this problem barrel, I produced a custom oversized gas piston to bring it to the same clearance as my original barrel/piston, and it works perfectly with the oversized piston. The custom piston I built for this barrel is so much larger it will not fit into any other barrel I own. But somehow this is within spec... whatever.

With barrel 3, an example of the degree and type of failure... with weaker (is there such a thing in 50AE?!) ammo like Armscor, Precision One, and American Quality, the slide often doesn’t travel back far enough to get behind a new round, and ends up between the rim and case for an instant stove pipe about half the time. Most of the time it closes on an empty chamber because it can’t even pick up a new round. Not fun at all… but within spec. I’m no gunsmith, gun-builder or firearms manufacturer repair center, so who am I to say it’s out of spec? It couldn’t be! It must be something else, like me limp-wristing or holding it wrong right? It isn’t like I have more barrels in the same caliber, multiple frames now, multiple slides and bolts, and even someone elses loaner frame to test with is it?

OH WAIT! I have all of the above, but only one set of elbows and wrists, so it must be those. But the issue magically goes away when I have either of the two other 6” barrels (#1 and #2) in 50AE that show not a single sign of issue with substantially less clearance in their gas cylinders and don’t need custom built gas pistons to function.

I will end the rant here... lets just be clear that you are on your own if you end up with a barrel like this and don’t buy your ammo from a dynamite manufacturer... but if you know this is your problem, at least you won’t pull your hair out figuring it out, in case you don’t have different frames, slides, etc to test with like I do.

Barrel 6… Now lets guess which other barrel has issues with lower power ammunition... you didn’t have to guess it was barrel number 6 in 44 Magnum. I also run a custom over-sized gas piston for this barrel… until I retired it like the 50AE. It wasn’t as problematic, but it was weak... how do I know? Because 4 brands/loadings of ammunition that would not cycle in barrel 6 work flawlessly in barrel 5. I guess nobody told barrel 6 it was within spec either… Dang, this is kind of hard to argue that one too. Or ordered some new less-limp wrists and a manual on how to shoot a Desert Eagle though. When they come in, I should be able to use this barrel without issue. (Ok! Ok! I’ll try to turn off the sarcasm, but I don’t own a boat for these anchors I keep paying for.)

Barrel 10… Yes it has a higher clearance, but this barrel doesn’t really have an issue even without a custom gas piston. This is because it is longer. If you have 6” and 10” barrels, you will probably already know that the longer barrel allows for a longer gas pulse, so slightly weaker rounds can often be used reliably. If you have rounds that barely run in your 6” barrel, they will usually run in a 10”.

Keep in mind that gas system clearance is only part of the picture in reliability. As I stated earlier, it is worth checking out, even with the relatively low precision of common calipers, it can show up. Gas piston clearance is worth ruling out.

Another common question I get... is relative to gas piston diameter consistency. The pistons I bought this year are within a few ten thousandths of an inch of my original 1993 piston. I have not seen out of spec gas pistons before personally. My original gas piston has over 6000 rounds of 50, 44, 357, and a handful of 429’s now. (note, I do not make custom gas pistons for others.)

How you hold most any automatic pistol can have an effect on function of course. If death-grips and locked elbows allow me to shoot cheaper or lower powered ammo, I understand why and what is going on. But the point of this post is that the gas system CAN be far enough off to be the CAUSE of malfunction, so “Limp-Wristing, it might not be your fault…”

I have read and been given suggestions on what I might be doing wrong to cause malfunctions... but from my perspective it is just a case of accidentally putting a poor quality barrel on.

“Maybe that Israeli gun just doesn’t like US made barrels…” I put my Desert Eagle through some sensitivity training and it didn’t seem to be the issue... My Desert Eagles (multiple now) don’t seem to be racist at all actually. They do seem a bit biased against over-sized gas cylinders however. Maybe there is some training for that too.

I hope the effort of sharing my path to function can help you get your Desert Eagle running as they are very capable of... reliably… but it is also important to understand that in some cases, regardless of what you might be told by those who are paid to know, there is some chance that problems with your Desert Eagle might not be anything you are doing wrong or any wear part you can replace.

Good luck, and happy shootin!

MrBlackCat

The intent of this writing is to possibly aid in troubleshooting a problem pistol. If nothing else, should you have trouble with a Desert Eagle, you could use this information to rule out a high-tolerance gas cylinder as part of the issue.

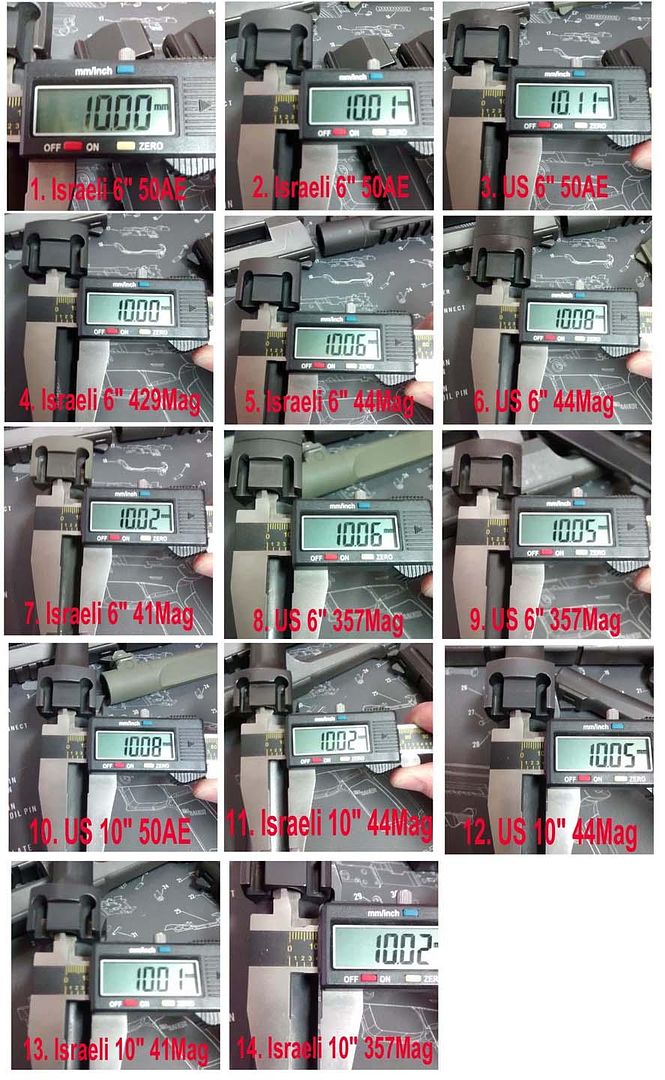

First off… a picture is worth at least 1000 words… so have a look at 14 barrels I currently own…

# Barrel Length Diameter

1 Israeli 6 50AE 10.00mm

2 Israeli 6 50AE 10.01mm

3 US 6 50AE 10.11mm

4 Israeli 6 429DE 10.00mm

5 Israeli 6 44Mag 10.06mm

6 US 6 44Mag 10.08mm

7 Israeli 6 41Mag 10.02mm

8 US 6 357Mag 10.06mm

9 US 6 357Mag 10.05mm

10 US 10 50AE 10.08mm

11 Israeli 10 44Mag 10.05mm

12 US 10 44Mag 10.02mm

13 Israeli 10 41Mag 10.01mm

14 Israeli 10 357Mag 10.02mm

Although I live in the US, I used metric measures because of the higher resolution.

Even with the relatively low precision of calipers, have a look at the numbers relative to each other and you will see where this is going pretty quickly.

Jumping straight in...

Barrel number 1 is my very first 1993 Mk VII 50AE barrel. It has over 4000 rounds through it at this point. With this barrel and its gas cylinder dimensions, you will never understand the term “limp-wristing” because it doesn’t happen… this is mostly due to optimal (proper?) gas cylinder clearance, between the piston and cylinder.

Barrel number 3… the third barrel I bought. I wanted a muzzle brake on a 50AE barrel, and didn’t want to modify my original barrel, so I bought this barrel for that purpose… but it doesn’t work well enough to bother using. I have posted about this in other threads, but long story short, it has been back to Magnum Research twice and I am told it functions fine and is within spec. The point being that if you have this issue, you are probably on your own. They must test these things in a vice, with dynamite for ammo is all I can figure.

With barrel 3, some functionality can be achieved with the hottest of rounds, locked elbows, and the muzzle brake helped, probably by keeping the gun more flat.

However... before I retired this problem barrel, I produced a custom oversized gas piston to bring it to the same clearance as my original barrel/piston, and it works perfectly with the oversized piston. The custom piston I built for this barrel is so much larger it will not fit into any other barrel I own. But somehow this is within spec... whatever.

With barrel 3, an example of the degree and type of failure... with weaker (is there such a thing in 50AE?!) ammo like Armscor, Precision One, and American Quality, the slide often doesn’t travel back far enough to get behind a new round, and ends up between the rim and case for an instant stove pipe about half the time. Most of the time it closes on an empty chamber because it can’t even pick up a new round. Not fun at all… but within spec. I’m no gunsmith, gun-builder or firearms manufacturer repair center, so who am I to say it’s out of spec? It couldn’t be! It must be something else, like me limp-wristing or holding it wrong right? It isn’t like I have more barrels in the same caliber, multiple frames now, multiple slides and bolts, and even someone elses loaner frame to test with is it?

OH WAIT! I have all of the above, but only one set of elbows and wrists, so it must be those. But the issue magically goes away when I have either of the two other 6” barrels (#1 and #2) in 50AE that show not a single sign of issue with substantially less clearance in their gas cylinders and don’t need custom built gas pistons to function.

I will end the rant here... lets just be clear that you are on your own if you end up with a barrel like this and don’t buy your ammo from a dynamite manufacturer... but if you know this is your problem, at least you won’t pull your hair out figuring it out, in case you don’t have different frames, slides, etc to test with like I do.

Barrel 6… Now lets guess which other barrel has issues with lower power ammunition... you didn’t have to guess it was barrel number 6 in 44 Magnum. I also run a custom over-sized gas piston for this barrel… until I retired it like the 50AE. It wasn’t as problematic, but it was weak... how do I know? Because 4 brands/loadings of ammunition that would not cycle in barrel 6 work flawlessly in barrel 5. I guess nobody told barrel 6 it was within spec either… Dang, this is kind of hard to argue that one too. Or ordered some new less-limp wrists and a manual on how to shoot a Desert Eagle though. When they come in, I should be able to use this barrel without issue. (Ok! Ok! I’ll try to turn off the sarcasm, but I don’t own a boat for these anchors I keep paying for.)

Barrel 10… Yes it has a higher clearance, but this barrel doesn’t really have an issue even without a custom gas piston. This is because it is longer. If you have 6” and 10” barrels, you will probably already know that the longer barrel allows for a longer gas pulse, so slightly weaker rounds can often be used reliably. If you have rounds that barely run in your 6” barrel, they will usually run in a 10”.

Keep in mind that gas system clearance is only part of the picture in reliability. As I stated earlier, it is worth checking out, even with the relatively low precision of common calipers, it can show up. Gas piston clearance is worth ruling out.

Another common question I get... is relative to gas piston diameter consistency. The pistons I bought this year are within a few ten thousandths of an inch of my original 1993 piston. I have not seen out of spec gas pistons before personally. My original gas piston has over 6000 rounds of 50, 44, 357, and a handful of 429’s now. (note, I do not make custom gas pistons for others.)

How you hold most any automatic pistol can have an effect on function of course. If death-grips and locked elbows allow me to shoot cheaper or lower powered ammo, I understand why and what is going on. But the point of this post is that the gas system CAN be far enough off to be the CAUSE of malfunction, so “Limp-Wristing, it might not be your fault…”

I have read and been given suggestions on what I might be doing wrong to cause malfunctions... but from my perspective it is just a case of accidentally putting a poor quality barrel on.

“Maybe that Israeli gun just doesn’t like US made barrels…” I put my Desert Eagle through some sensitivity training and it didn’t seem to be the issue... My Desert Eagles (multiple now) don’t seem to be racist at all actually. They do seem a bit biased against over-sized gas cylinders however. Maybe there is some training for that too.

I hope the effort of sharing my path to function can help you get your Desert Eagle running as they are very capable of... reliably… but it is also important to understand that in some cases, regardless of what you might be told by those who are paid to know, there is some chance that problems with your Desert Eagle might not be anything you are doing wrong or any wear part you can replace.

Good luck, and happy shootin!

MrBlackCat